bearing steel

Bearing steel is the steel used to make balls, rollers, and bearing rings. Bearing steel, also known as high carbon chromium steel, has a carbon content of ωc of about 1% and a chromium content of ωcr of 0.5%-1.65%. Bearing steel is divided into six categories: high carbon chromium bearing steel, chromium-free bearing steel, carburized bearing steel, stainless bearing steel, medium and high temperature bearing steel and antimagnetic bearing steel.

Bearing steel has high and uniform hardness and wear resistance, as well as high elastic limit. The requirements for the uniformity of the chemical composition of the bearing steel, the content and distribution of non-metallic inclusions, and the distribution of carbides are very strict, and it is one of the most stringent steel grades in all steel production.

Email: [email protected]

WhatsApp: 0086-13788924073

The described bearing steels and steels for rolling bearings are defined by PN-74/H-84041, BN-72/H-0641-06, and PN-EN ISO 683-17, according to which the company provides:

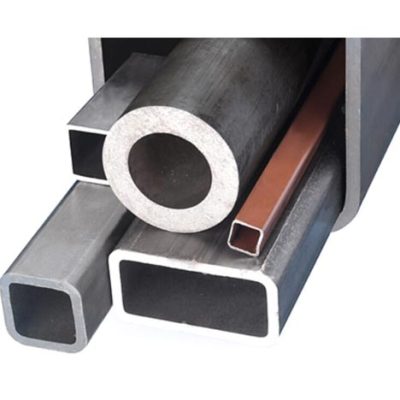

● Seamless bearing tubes according to PN-72/H-74250

● Rolled bearing sheets

● Forgings and forged bars according to PN-91/H-94011, EN 10250

● Cold-rolled bearing sheets according to PN-75/H-92335

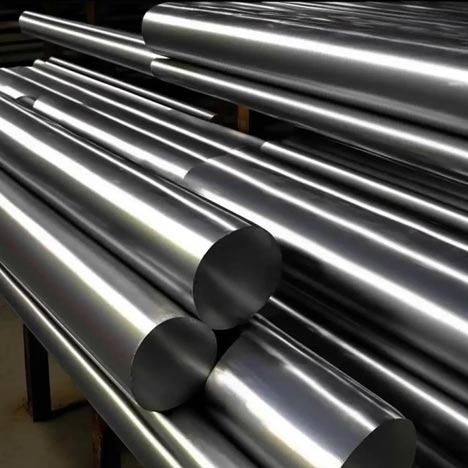

● Rolled bearing steel bars according to PN-75/H-93200, PN-55/H-93216, PN-55/H-93217, PN-72/H-93201, PN-EN 10059, PN-55/H-93218, PN-72/H-93202, PN-EN 10058,

● Light bars made of bearing steel PN-72/H-93208, PN-86/H-93209, PN-85/H-93210, PN-EN 10278

● Bearing drawn wires PN-72/H-93208, PN-85/H-93210, PN-EN 10278

Supply Range of Bearing Steel

● Steel Round Bar: diameter 8mm – 800mm

● Steel Plate: thickness 2mm –300mm x width 200mm – 800mm

● Other sizes of steel as per customer’s requirements

● Process: Cold drawn, hot rolled, forged etc.

● Surface Finish: black, rough machined, turned, polished or as per given requirements.

| Spec | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Ni | Hardness |

|---|---|---|---|---|---|---|---|---|---|

| SAE52100 100Cr6 SUJ2 |

0.95 ~ 1.10 | 0.15- 0.35 |

0.50 max |

0.025 max |

0.025 max |

1.30 ~ 1.60 |

64 HRC max |

||

| AISI440C SUS440C X105CrMo17 |

0.95 ~ 1.20 | 1.00 max |

1.00 max |

0.04 max |

0.03 max |

16.0 ~18.0 |

0.75 max | 58 HRC max |

|

| KS440 ACD34 X65Cr13 |

0.60 ~ 0.75 | 1.00 max |

1.00 max |

0.03 max |

0.02 max |

11.5 ~13.0 |

0.3 max | 60 HRC max |

|

| AISI420 SUS420 X20Cr13 |

0.26 ~ 0.35 | 1.00 max |

1.50 max |

0.04 max |

0.03 max |

12.0 ~14.0 |

55 HRC max |

||

| AISI304 SUS304 X5CrNi1810 |

0.08 max |

0.75 max |

2.00 max |

0.045 max |

0.03 max |

18.0 ~20.0 |

8.0 ~ 10.5 |

39 HRC max |

|

| AISI316 SUS316 X5CrNiMo17- 12- 2 |

0.08 max |

1.00 max |

2.00 max |

0.045 max |

0.03 max |

16.0 ~18.0 |

2.0 ~ 3.0 |

10.0 ~14.0 |

39 HRC max |

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.