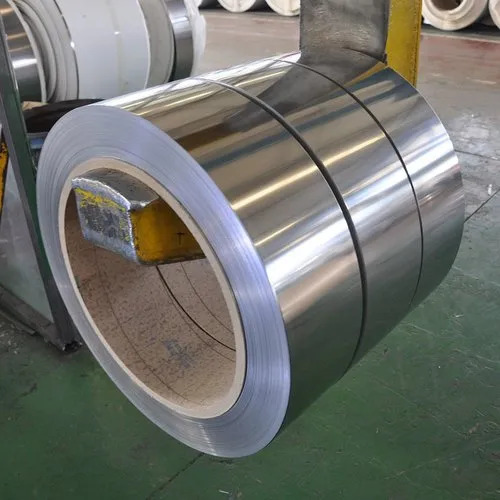

Ferritic Stainless Steel 400 Series

400 series ferritic stainless steel is a nickel-free, low-nickel stainless steel, and its formability, corrosion resistance, oxidation resistance is good, known as "economical" stainless steel.There are five types of ferritic stainless steels, three standard grades and two special grades.

So far, the largest and most widely used are mainly standard steel grades. Therefore, the general standard ferritic stainless steel can fully meet and apply to the needs of most application scenarios.

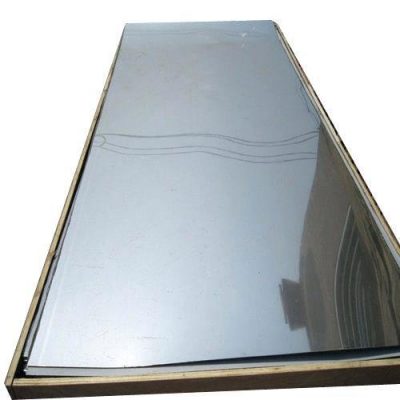

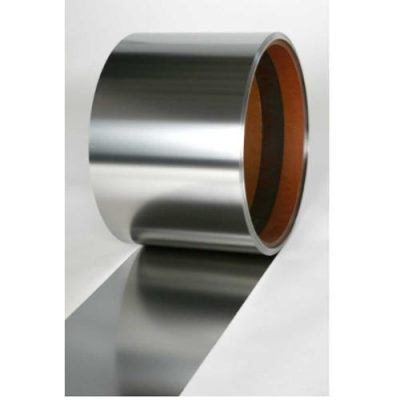

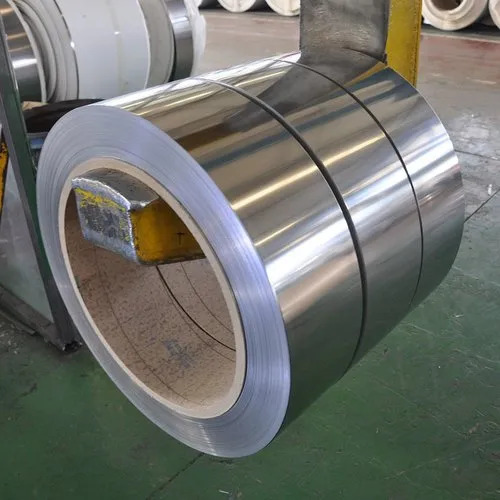

Supplied Forms: Sheet, Strip, Tube, Bar, Fittings & Flanges, Pipe, Plate

Email: [email protected]

WhatsApp: 0086-13788924073

| GB | JIS | America | KS | BS EN | IS | AS | CNS | |||

| Old | New(07.10) | ASTM | UNS | |||||||

| 0Crl3Al | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 | |

| - | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L | |

| 00Cr12 | 022Cr12 | SUS410L | - | - | STS410L | - | - | 410L | 410L | |

| 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 | |

| 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 | |

| - | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 | |

| Product | Ferritic Seamless Stainless Steel Tubes |

| Size | OD: 19.05-76.2mm |

| Thickness | 0.5mm to 12.7mm |

| Length | up to 24m |

| Standards | ASTM A688/ A268M, ASME SA268/ SA268M |

| Applicatiobn | Automotive application, Kitchenware, Industrial Equipment, Cutlery, Aerospace and General Engineering |

| Certification | EN 10204 3.1 |

| Testing | Hydro Tested, Chemical, Mechanical Test, PMI |

| Inspection | Third Party Inspection, Buyer Inspection |

| Packing | Weaving Bag, Seaworthy Bundles, Wooden Case if required |

| Delivery Condition | Annealed and Pickled, Bright and Annealed |

| Delivery Time | 1-2 Days for Material in Stock, 7-30 Days for Make to Order Materials |

| Packaging Details | KNITTED PLASTIC BAG BUNDLE / WOODEN CASE OR ACCORING TO CUSTOMER REQUEST |

| Minimum Order Quantity | 0.5-1 TON |

1. (409 or 410L stainless steel)

This type of steel has the lowest chromium content of all stainless steels, is therefore the cheapest, and is best suited for use in environments with no or slight corrosion, and allows for slight localized rusting. 409 stainless steel was originally designed specifically for automotive exhaust systems (which are less corrosive to the outside world). Stainless steel is commonly used in containers, buses, coaches, and more recently as an outer frame for LCD displays.

2. (430 stainless steel)

This is the most widely used type of ferritic stainless steel, containing high chromium, good corrosion resistance, and most properties are similar to 304. It can replace 304 stainless steel. In some application scenarios, it is generally used indoors and has sufficient corrosion resistance. The main uses are washing machine drum, lining board and so on. Usually 430 stainless steel is often used as a substitute for 304 for kitchen equipment, dishwashers, kettles, pots, etc.

3. (including 430Ti, 439, 441 stainless steel, etc.)

This grade has better weldability and formability than the second grade. It's even better than 304 stainless in most cases. Common applications include sinks, heat exchangers (sugar industry, energy, etc.), automotive exhaust systems (longer life than 409), and welded parts of washing machines. The third brand can even be used in place of 304 stainless steel in applications with higher performance requirements.

4. (including 434, 436, 444 stainless steel and other types)

These grades use molybdenum added to improve corrosion resistance and are commonly used in hot water tanks, solar water heaters, automotive exhaust systems, electric kettle and microwave components, automotive trim strips, and outdoor panels. The corrosion resistance of steel is comparable to 316.

5. (including 446, 445/447 stainless steel, etc.)

By adding more chromium and molybdenum, the corrosion and oxidation resistance of the product is improved. The corrosion resistance and oxidation resistance of these grades are better than 316. Coastal and other common use high corrosion resistant environments.

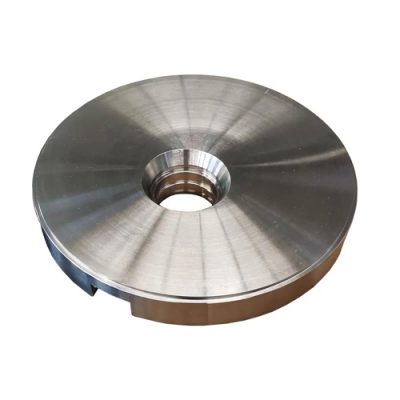

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.