Inconel 718

Inconel 718 is a Gamma Prime strengthened alloy with excellent mechanical properties at elevated temperatures, as well as cryogenic temperatures. Suitable for temperatures upto around 1300 F. Can be readily worked and age hardened.

Excellent strength from -423 degrees F to 1300 degrees F (-253 degrees C to 705 degrees C). Age hardenable and may be welded in fully aged condition, Excellent oxidation resistance up to 1800 degrees F (980 degrees C). Typically sold in the solution annealed temper, but can be ordered aged, cold worked, or cold worked & aged.

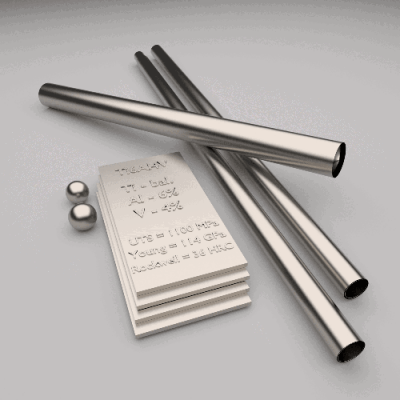

Inconel 718 in this grade in the following forms: Bar, flat bar, wire cuts, loose coil, wire reel, sheet, plate, tube, fitting, disk, machined.

Standards: AMS 5596, AMS 5662, ASTM B637, UNS N07718

Product size can be customized according to customer needs.

Email: [email protected]

WhatsApp: 0086-13788924073

● Any type and size can be custom made.

● Minimum order quantity: from 10 kg

● Payment method: FOB Shanghai etc., CNY or USD

● Shipping method: sea, railway, air transport

● Packing: strong packaging

| Form | Standard |

|---|---|

| Metal Type | UNS N07718 |

| Bar | ASTM B637 AMS 5662 AMS 5663 AMS 5664 PWA 1009 PWA 1010 GE B50TF15 |

| Wire | AMS 5832 |

| Sheet | ASTM B670 AMS 5596 AMS 5597 PWA 1033 GE B50TF14 ASTM B670 ASTM B637 |

| Plate | ASTM B670 AMS 5596 AMS 5597 PWA 1033 GE B50TF15 ASTM B670 ASTM B637 |

| Tube | AMS 5589 AMS 5590 |

| Pipe | AMS 5589 AMS 5590 |

| Fitting | |

| Forging | ASTM B637 AMS 5562 AMS 5663 AMS 5664 PWA 1009 PWA 1010 GE B50TF15 |

| Weld Wire | A5.14 ERNiFeCr-2 |

| Weld Electrode | |

| Din | 2.4668 |

| Product Name | Monel / Hastelloy / INCOLOY Alloy | ||

| Type | Bar / Rod | Pipe /Tube | Plate/Sheet |

| Size | φ4-50mm;or as required Length:2000-12000mm |

φ6-273mm;δ1-30mm;or as required Length:1000-12000mm |

Width:40-3500mm,or as required Length:As Required |

| Standard | ASTM,JIS, AISI, GB, DIN, EN | ||

| Grade (ASTM UNS) |

Inconel: Inconel100,Inconel 600,Inconel 601,Inconel602CA Inconel 617, Inconel 625LCF, Inconel 686 Inconel 690 Inconel 718, Inconel 725, Inconel X-750 Hastelloy: Hastelloy B, Hastelloy B-2, Hastelloy B-3, Hastelloy C Hastelloy C-22, Hastelloy C-4, Hastelloy C-276 Hastelloy C-2000, Hastelloy G, Hastelloy G-3 Hastelloy G-35 Monel: Monel 400, Monel 401, Monel 404, Monel R405 Monel K-500 Nickel: Nickel 200, Nickel 201, Nickel 205 Nimonic: Nimonic 75, Nimonic 80A, Nimonic 90,Nimonic 105 Nimonic 115, Nimonic 901 Udimet: Udimet 188, Udimet 720, Udimet R41, Udimet 300 Haynes: Haynes 230, Haynes 556, Haynes 188 Incoloy: Incoloy 800, Incoloy 800H, Incoloy 800HT, Incoloy 825, Incoloy 925, Incoloy 926 GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 Alloy: Alloy 20/28/31; |

||

| Grade (EN) | 2.4060, 1.4980, 1.4529, 2.4460, 1.4563, 1.4886, 1.4876, 1.4876, 2.4858, 2.4816, 2.4851, 2.4856, 2.4856, 2.4668, 2.4669, 2.4360, 2.4375, 2.4819 | ||

| Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting | ||

| Technique | Cold Rolled Hot Rolled | ||

| Edge | Mill Edge / Slit Edge | ||

| Supply Ability | 5000 Ton/Tons per Month | ||

Chemistry

| Chemical Requirements | |||||||

|---|---|---|---|---|---|---|---|

| Ni | Fe | Mo | Mn | Si | Cr | C | |

| Max | 55.0 | Bal | 3.30 | 0.35 | 0.35 | 21.0 | 0.08 |

| Min | 50.0 | 2.80 | 17.0 | ||||

Tensile Data

| Mechanical Property Requirements | |||||

|---|---|---|---|---|---|

| Ultimate Tensile | Yield Strength (0.2% OS) | Elong. in 2 in. (50mm) or 4D min, % | R/A | Hardness Brinell | |

| Min | 185 KSi | 150 KSi | 12 | 15 | 331 |

| Max | |||||

| Min | 1275 MPa | 1034 MPa | |||

| Max | |||||

Uses for Inconel 718 tend to be in the field of gas turbine components and cryogenic storage tanks. Jet engines, pump bodies and parts, rocket motors and thrust reversers, nuclear fuel element spacers, hot extrusion tooling. Other popular uses are high strength bolting, and down hole shafting.

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.