Austenitic stainless steel 300 series

Austenitic stainless steel refers to stainless steel with austenitic structure at room temperature. When the steel contains about 18% Cr, 8%~10% Ni, and about 0.1% C, it has a stable austenite structure.

Austenitic 300 series stainless steels are complex-nickel austenitic stainless steels.Austenitic chromium-nickel stainless steel includes the well-known 18Cr-8Ni steel and high Cr-Ni series steel developed on this basis by increasing the content of Cr and Ni and adding Mo, Cu, Si, Nb, Ti and other elements.

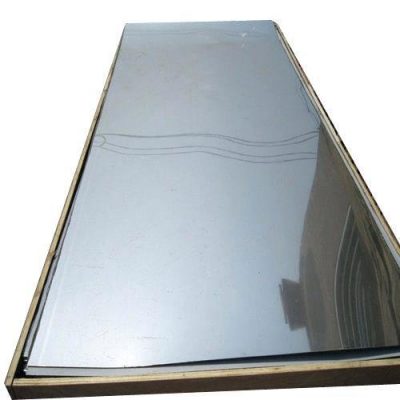

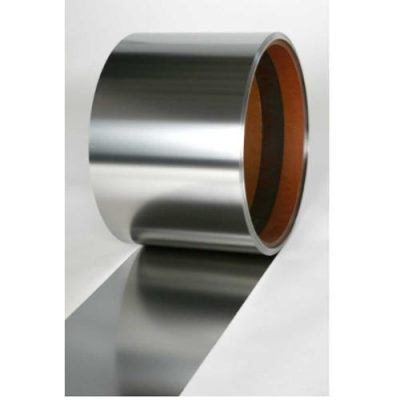

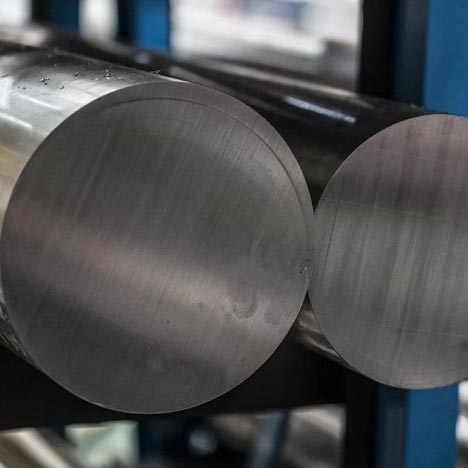

The production process of austenitic stainless steel has good performance, especially chromium-nickel austenitic stainless steel. The conventional means of producing special steel can smoothly produce various commonly used specifications of plates, tubes, strips, wires, bars, forgings and castings.

Email: [email protected]

WhatsApp: 0086-18939717601

| Material | Known As | Material Specification | Stock Form | (Min.–Max. mm) |

|---|---|---|---|---|

| SUS304 | S30400 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4301 |

Cold finished round bars | φ2-50 |

| Peeled round bars | φ16-250 | |||

| Knurled round bars | φ6-30 | |||

| Hex bars | H8-80 | |||

| Square bar(Cold) | □5-50 | |||

| SUS304L | S30403 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4306 |

Cold finished round bars | φ6-13 |

| Peeled round bars | φ16-250 | |||

| Hex bars | H14-70 | |||

| SUS316 | S31600 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4401 |

Cold finished round bars | φ2-30 |

| Peeled round bars | φ16-250 | |||

| Hex bars | H8-80 | |||

| SUS316L | S31603 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4404 |

Cold finished round bars | φ2-30 |

| Peeled round bars | φ20-250 | |||

| Hex bars | H8-70 | |||

| SUS316Ti | S31635 | ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4571 |

Peeled round bars | φ16-200 |

| SUS303 | S30300 | JIS G4318 JIS G4303 ASME A582 EN 1.4305 |

Cold finished round bars | φ3-30 |

| Peeled round bars | φ20-100 | |||

| Knurled round bars | φ6-30 | |||

| Hex bars | H5.5-46 | |||

| SUS317L | S31703 | JIS G4318 JIS G4303 |

Cold finished round bars | φ8-13 |

| Peeled round bars | φ16-60 | |||

| Hex bars | H17-30 | |||

| SUS310S | S31008 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4845 |

Cold finished round bars | φ3-18.3 |

| Peeled round bars | φ16-150 | |||

| Hex bars | H8-46 | |||

| SUS321 | S32100 | JIS G4318 JIS G4303 ASTM A182/A276/A479 ASME SA182/SA479 AMS5645 NACE MR0175/0103 EN1.4878 |

Cold finished round bars | φ6-14 |

| Peeled round bars | φ16-100 | |||

| Hex bars | H17-46 | |||

| S31254 | 254SMO | ASTM A182/A276/A479 ASME SA182/SA276/SA479 NACE MR0175/MR0103 EN 1.4547 |

Peeled round bars | φ10-150 |

| XM-19 (S20910) |

Nitronic50 | ASTM A182/A276/A479 ASME SA182/SA276/SA479 AMS 5764 NACE MR0175/MR0103 |

Peeled round bars | φ12.7-150 |

| GB | JIS | America | KS | BS EN | IS | AS | CNS | ||

| Old | New(07.10) | ASTM | UNS | ||||||

| 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

| 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Cr17Ni12Mo2 | 316L | 316L |

| 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

Model 301: Good ductility, for molding products. It can also be hardened by mechanical processing. Welding is good. Abrasion and fatigue strength is better than 304 stainless steel, products such as: spring, steel structure, wheel cover.

Model 303: By adding a small amount of sulfur and phosphorus, it is easier to cut and process than 304.

Model 304: General model; that is, 18/8 stainless steel. Products such as: corrosion containers, tableware, furniture, railing, medical equipment, some mobile phone frames. The standard component is 18 % chromium and 8 % nickel. Stainless steels that are not magnetic and cannot be changed by heat treatment methods to change their gold -phase tissue structure.

Model 304L: The same characteristics as 304, but low -carbon is more resistant to corrosion and easy to treat, but poor mechanical properties are suitable for welding and not easy to treat products.

Model 304N: The same feature as 304 is a kind of stainless steel containing nitrogen, which is to increase the strength of steel.

Model 309: It has better temperature resistance than 304.

Model 309s: multiple amounts of chromium, nickel, so heat -resistant, good antioxidant, products such as: heat exchangers, boiler components, jet engines.

Model 310s: contains up to the maximum chromium and nickel, so the best heat exchanger, boiler component, motor equipment for heat -resistant and antioxidant.

Model 316: Following 304, the second most widely used steel type is mainly used for the food industry and surgery equipment, adding molybdenum elements to obtain a special structure of corrosion. Because it has a better anti -chloride corrosion ability than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recycling devices. Level 18/10 stainless steel usually meets this application level. It is especially used in chemical, seaside and other easy corrosive environments, ship assembly, and building materials.

Model 316L: Low -carbon is more corrosion -resistant and easy to treat. Products such as chemical processing equipment, nuclear energy generators, and frozen storage.

Model 321: In addition to adding titanium to the risk of titanium reduction, other properties are similar to 304, which is suitable for welding winemaking equipment, steam pipes, and aviation parts.

Model 347: Add stable element 铌, suitable for welding aviation equipment parts and chemical equipment.

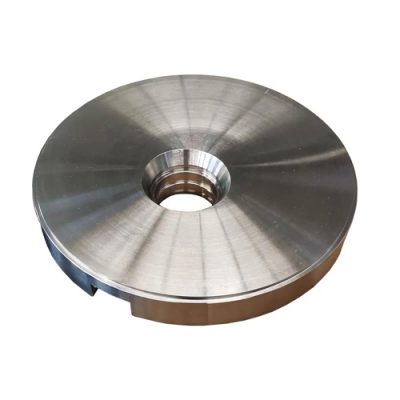

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.