spring steel

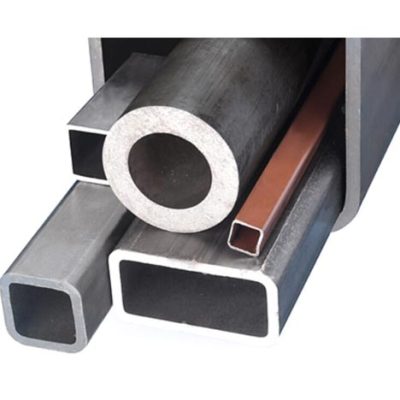

Spring steel refers to special steel grades for manufacturing various springs and other elastic components. Springs mainly include leaf springs, coil springs and other elastic elements. The main function is to absorb impact energy and ease mechanical vibration and impact.

Spring steel is divided into non-alloy spring steel (ie carbon spring steel) and alloy spring steel. Alloy spring steel: generally contains 0.45%~0.70% carbon and a certain amount of alloying elements such as Si, Mn, Cr, V, W and B. The addition of alloying elements improves the anti-relaxation properties of the spring steel and improves the toughness of the steel. Carbon spring steel: The steel contains 0.60%~0.90% carbon and 0.3%~1.20% manganese, no other alloying elements are added, and the cost is low.

Email: [email protected]

WhatsApp: 0086-13788924073

| Steel Grade | GB | ISO | AISI | JIS | DIN | NF |

| 20Cr | GB20Cr | 20Cr4 | 5120 | SCr22,SCrl20 | 20Cr4 | - |

| 30Cr | GB34Cr4 | 34Cr4 | 5130 | SCr2,SCr430 | 34Cr4 | 34Cr4 |

| 35Cr | GB35Cr | 34Cr4 | 5132 | SCr3,SCr435 | 34Cr4 | 34Cr4 |

| 40Cr | GB40Cr | 37Cr4 | 5140 | SCr4,SCr440 | 41Cr4 | 41Cr4 |

| 45Cr | GB45Cr | 41Cr4 | 5145 | SCr5,SCr445 | 41Cr4 | 41Cr4 |

| 50Cr | GB50Cr | - | 5150 | SCr445 | - | - |

| 20CrMo | - | 18CrMo4 | - | SCM22.SCM430 | - | 25CrMo4 |

| 30CrMo | GB30CrMo | 25CrMo4 | 4130 | SCM2,SCM430 | 25CrMo4 | 25CrMo4 |

| 30CrMoA | GB30CrMoA | 34CrMo4 | 4130 | SCM430 | 34CrMo4 | 34CrMo4 |

| 35CrMo | GB35CrMo | 34CrMo4 | 4137 | SCM3,SCM435 | 34CrMo4 | 34CrMo4 |

| 42CrMo | GB42CrMo | 42CrMo4 | 4140 | SCM440 | 42CrMo4 | 42CrMo4 |

| Steel Grade | Chemical Composition (%) | |||||||

| C | Mn | Si | S | P | Cr | Cu | Ni | |

| # 45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.30 |

| # 50 | 0.47-0.55 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.30 |

| # 55 | 0.52-0.60 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.30 |

| # 60 | 0.57-0.65 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.30 |

| # 70 | 0.67-0.75 | 0.50-0.80 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.30 |

| 65Mn | 0.62-0.70 | 0.90-1.20 | 0.17-0.37 | ≤0.035 | ≤0.035 | ≤0.25 | - | - |

| 55Si2Mn | 0.52-0.60 | 0.60-0.90 | 1.50-2.00 | ≤0.035 | ≤0.035 | ≤0.35 | - | - |

| 60Si2Mn | 0.56-0.64 | 0.60-0.90 | 1.50-2.00 | ≤0.035 | ≤0.035 | ≤0.35 | - | - |

| 60Si2MnA | 0.56-0.64 | 0.60-0.90 | 1.60-2.00 | ≤0.03 | ≤0.03 | ≤0.35 | - | - |

| 55CrMnA | 0.52-0.60 | 0.65-0.95 | 0.17-0.37 | ≤0.03 | ≤0.03 | 0.65-0.95 | - | - |

| 60CrMnA | 0.56-0.64 | 0.70-1.00 | 0.17-0.37 | ≤0.03 | ≤0.03 | 0.70-1.00 | - | - |

| 50CrVA | 0.46-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.03 | ≤0.03 | 0.80-1.10 | - | - |

| 60CrMnBA | 0.56-0.64 | 0.70-1.00 | 0.17-0.37 | ≤0.03 | ≤0.03 | 0.70-1.00 | - | - |

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.