Corrosion resistant alloy

Corrosion-resistant alloy is a kind of metal anti-corrosion material, which is a kind of special alloy, but it cannot be used in fluorine-containing environment. Compared with non-metallic anti-corrosion materials, metal anti-corrosion materials mainly include iron-based alloys (corrosion-resistant stainless steel); nickel-based alloys (Ni-Cr alloys, Ni-Cr-Mo alloys, Ni-Cu alloys, etc.); active metals .

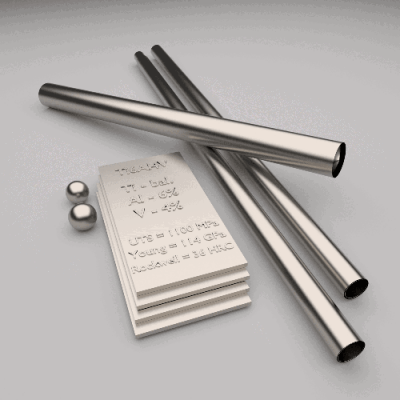

Available Product Forms:

Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire.

Email: [email protected]

WhatsApp: 0086-18939717601

1. Corrosion-resistant stainless steel

Mainly refers to the ordinary 300 series stainless steel 304 that is resistant to corrosion by the atmosphere or seawater, the most common corrosion-resistant alloy Hastelloy 316L, 317L, etc.; austenitic stainless steel 904L, 254SMO with strong corrosion resistance; dual-phase steel 2205, 2507 etc.; corrosion-resistant alloy 20 alloy containing CU, etc.

2. Nickel-based corrosion-resistant alloys

Mainly Hastelloy and NI-CU alloys, etc. Since the metal NI itself is a face-centered cubic structure, the crystallographic stability enables it to accommodate more alloying elements than FE, such as CR, MO, etc., so as to achieve resistance At the same time, nickel itself has certain anti-corrosion ability, especially the ability to resist stress corrosion caused by chloride ions. In strong reducing corrosive environments, complex mixed acid environments, and solutions containing halogen ions, nickel-based corrosion-resistant alloys represented by Hastelloy have absolute advantages over iron-based stainless steels.

3. Active Metals

Typical representatives with good corrosion resistance are TI; ZR; TA, etc. The most typical representative is TI; titanium has a wide range of applications, mainly used in some corrosive environments that stainless steel cannot adapt to.

Principle of corrosion resistance of titanium materials: In an oxidizing atmosphere, a dense oxide film is formed to provide protection; therefore, it is generally not used in corrosive environments with strong reducibility or high sealing properties. At the same time, the application temperature of titanium materials is generally less than 300 degrees Celsius. It is important to note that none of the active metals can be used in fluorine-containing environments.

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Incoloy800 | N08800 | 1.4876 | NCF800/2B | NCF800 | GH20 | 0Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||

| Incoloy800H | N08810 | 1.4958 | NCF800H | 1Cr20Ni32AlTi | X10NiCrAlTi32-20 | |||||

| Incoloy800HT | N08811 | 1.4959 | 0Cr25Ni35AlTi | |||||||

| Incoloy825 | N08825 | 2.4858 | NCF825 | NCF825 | 0Cr21Ni42Mo3Cu2Ti | NiCr21Mo | ||||

| Incoloy901 | ||||||||||

| Incoloy925 | N09925 | |||||||||

| Incoloy926 | N08926 | 1.4529 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel601 | N06601 | 2.4851 | NCF601 | NCF601 | 1Cr23Ni60Fe13Al | NiCr23Fe | ||||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | ||||

| Inconel690 | N06690 | 2.4642 | 0Cr30Ni60Fe10 | NiCr29Fe | ||||||

| Inconel718 | N07718 | 2.4668 | GH169 | NiCr19Fe19Nb5Mo3 | ||||||

| Inconel725 | N07725 | |||||||||

| Inconel X-750 | N07750 | 2.4669 | NCF750 | GH145 | XCr15Fe7TiAl | |||||

| HC-276 | N10276 | 2.4819 | 00Cr15Ni60Mo16W5Fe5 | NiMo15Cr15W | ||||||

| HB | N10001 | 2.4800* | 0Ni65Mo28Fe5V | S-NiMo 30 | ||||||

| HB-2 | N10665 | 3.4617 | 00Ni70Mo28 | NiMo28 | ||||||

| HB-3 | N10675 | 2.4600* | NiMo29Cr | |||||||

| HC | N10002 | 2.4819 | 0Cr15Ni60Mo16W5Fe5 | NiMo16Cr15W | ||||||

| HC-4 | N06455 | 2.4610* | 00Cr16Ni65Mo16Ti | NiMo16Cr16Ti | ||||||

| HC-22 | N06022 | 2.4602 | NiMo21Cr14W | |||||||

| HC-2000 | N06200 | 2.4675 | NiCr23Mo16Cu | |||||||

| Hastelloy-X | N06002 | 2.4465 | ||||||||

| Monel400 | N04400 | 2.4360,2.4361 | ||||||||

| MonelK500 | N05500 | 2.4375 | ||||||||

| Monel401 | N04401 | |||||||||

| Monel404 | 2.4867 | |||||||||

| Ni 200 | N02200 | 2.4066 | ||||||||

| Ni 201 | N02201 | |||||||||

| Nitronic50 | S20910 | XM-19 | ||||||||

| Nitronic60 | S21800 | Alloy218 | ||||||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| Alloy31 | N08031 | 1.4562 | X1NiCrMoCu 32-28-7 | |||||||

| Alloy33 | N08033 | 1.4591 | X1NiCrMoCuN 33-32-1 | |||||||

| ASTM | UNS | W-Nr. | JIS | KS | Element | DIN EN/DIN | ||||

| Alloy20 Cb-3 | N08020 | 2.4660* | Carpeter20Cb-3 | 0Cr20Ni35Mo3Cu4Nb | NiCr20CuMo | |||||

| IncoloyA-286 | S66286 | 1.4980,1.4944 | SUH660 | |||||||

| Incoloy800 | NO8800 | 1.4876 | NCF800B | NCF2B | GH20 | 0Cr20Ni32AlTi | X2NiCrAlTi3220 | |||

| Nimonic75 | 2.4951 | |||||||||

| N06219 | 2.4855 | NiCr19Mo9Si | ||||||||

| HastelloyX | N06002 | 2.4613 | ||||||||

| Inconel600 | N06600 | 2.4816 | NCF1B | NCF600 | GH600 | 1Cr15Ni75Fe8 | NiCr15Fe8 | |||

| Inconel625 | N06625 | 2.4856 | NCF625 | NCF625 | NS3306 | 0Cr20Ni65Mo10Nb4 | NiCr22Mo9Nb | |||

| InconelX-750 | N07750 | 2.4669 | NCF750 | XCr15Fe7TiAl | ||||||

| Nimonic80A | N07080 | 2.4952 | ||||||||

| Inconel718 | N07718 | 2.4668 | GH4169 | |||||||

| Inconel725 | N07725 | |||||||||

| Incoloy925 | N09925 | |||||||||

| Inconel600 | N06600 | 2.4816 | NCF600 | NCF1B | 1Cr15Ni75Fe8 | LC-NiCr15Fe | ||||

| PB | ||||||||||

| Alloy4 | ||||||||||

| Alloy31 | N08031 | 1.4562 | ||||||||

| F15 | ||||||||||

| Invar36 | K93600 | 1.3912 | ||||||||

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex:2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy: Alloy 20/28/31 | |

| Hastelloy:HastelloyB/ -2/B-3/C22/C-4/S/C276/C-2000/G-35/G-30/X/N/g | |

| Hastelloy B/UNS N10001, Hastelloy B-2/UNS N10665/DIN W. Nr. 2.4617, Hastelloy C, Hastelloy C-4/UNS N06455/DIN W. Nr. 2.4610, Hastelloy C22/UNS N06022/DIN W. Nr. 2.4602, Hastelloy C276/UNS N10276/DIN W. Nr. 2.4819, Hastelloy X/UNS N06002/DIN W. Nr. 2.4665 |

|

| Haynes: Haynes 230/556/188 | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20 | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

|

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60 | |

| Nimonic: Nimonic 75/80A/90/A263 | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

We can provide customized services according to customer requirements