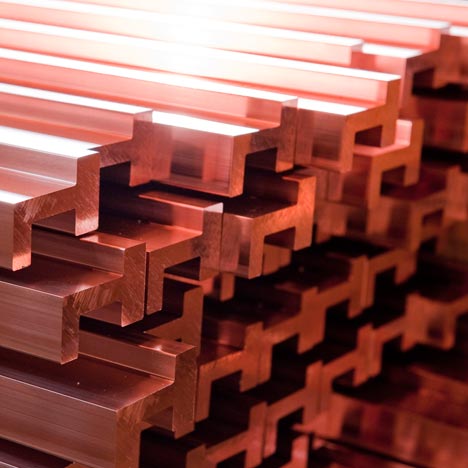

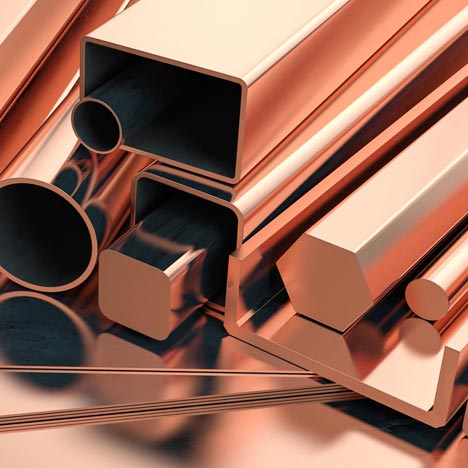

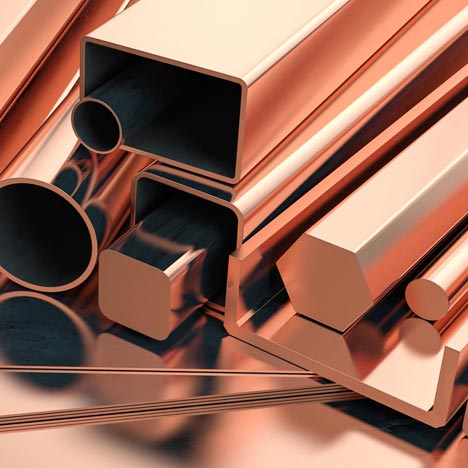

Copper Profiles

Profile is a kind of material that is not made into a flat shape but a variety of shapes according to the requirements of building design, or with a variety of surface carving. For a long time, plastic profile extrusion processing, in China's plastic processing industry has been a relatively weak category, the use of a single screw extruder, extrusion die at a low rate (1 m/ min or so) production of relatively simple section of the profile.

The company profile quality is reliable, welcome to order.

Email: [email protected]

WhatsApp: 0086-13788924073

1. Very good performance. From the copper profile with high strength, good toughness, good ductility these characteristics we can see that this profile has a very good performance of this application advantage, can rely on this aspect of the application advantage, effectively resist the adverse effects of various external factors.

2. The structure is stable. With high strength, good toughness of these characteristics, the overall structure of copper profile must be very stable, with such a structure, profile can achieve stable and reliable application, has been normal function.

3. Long service life. With rich characteristics, and have many advantages of performance, copper profile can be used in the application, effectively avoid the adverse effects of various external factors, so that the profile is bound to have a long service life.

| Grade list of copper and copper alloys by country | |||||||

| Classification | China | Germany | America | Japan | England | Europe | International |

| oxygen free copper | TU1 | 2.0076 | C10200 | C1020R | C103 | ||

| TU2 | Cu-OF-H110 | C11000 | c1011 | C101 | |||

| Vacuum oxygen free copper | E-Cu58 | TU00 | c1020 | 6N | |||

| high purity | copper-OFE | c10500 | c10700 | ||||

| Silver copper | TAg 0.1 | CuAg 0.1 | C10400 | C1040 | CuAg 0.1 | ||

| brass | H90 | CuZn10 | C22000 | C2200 | CZ101 | CuZn10 | CW501L |

| H70 | CuZn30 | C26000 | C2600 | CZ106 | CuZn30 | CW505L | |

| H68 | C26200 | C2620 | CuZn33 | CW506L | |||

| H65 | CuZn35 | C27000 | C2700 | CZ107 | CuZn36 | CW507L | |

| H63 | CuZn37 | C27200 | C2720 | CZ108 | CuZn37 | CW508L | |

| H62 | CuZn40 | C28000 | C2800 | CZ109 | CW509L | ||

| bronze | QSn4-0.3 | CuSn4 | C51100 | C5111 | PB101 | CuSn4 | CW450K |

| CuSn5 | C51000 | C5101 | CuSn5 | CW451K | |||

| QSn6.5-0.1 | CuSn6 | C51900 | C5191 | PB103 | CuSn6 | CW452K | |

| QSn8-0.3 | CuSn8 | C52100 | C5210 | CuSn8 | CW453K | ||

| QSn6.5-0.4 | |||||||

| copper-nickel | BZn18-18 | CuNi18Zn20 | C75200 | C7521 | NS106 | CuNi18Zn20 | |

| BZn18-26 | CuNi18Zn27 | C77000 | C7701 | NS107 | CuNi18Zn27 | CW410J | |

| BZn15-20 | C7541 | CW409J | |||||

| BZn18-10 | C7350 | ||||||

| pure copper | TU2 | OF-Cu58 | C10100 | C1011 | C101 | CW008A | copper oxide |

| T2 | SW——copper | C11000 | C1100 | C101 | copper - FRHC | ||

| TP2 | SF-Cu | C12200 | C1220 | C106 | CW024A | copper - DHP | |

| TP1 | SW-copper | C12000 | C1201 | CW023A | copper DLP | ||

According to EN 13601

| Alloy | Temper | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness(HB) | Conductivity(MS/m) |

| Cu-ETP | D (Hard as drawn) | - | - | - | - | 56 min |

| H035 | - | - | - | 35 -65 | 58 min | |

| R200 | 200 min | 120 max | 25 min | - | 58 min | |

| H065 | - | - | - | 65 -90 | 57 min | |

| R230 | 230 min | 160 min | - | - | 57 min | |

| R250 | 250 min | 200 min | 8 min | - | 57 min | |

| H085 | - | - | - | 85 -110 | 57 min | |

| R300 | 300 min | 260 min | 5 min | - | 57 min |

According to ASTM B 187

| Alloy | Temper | Rod & Bar Strength(mm) | Elongation(%) | Hardness(HV) | Conductivity(MS/m) |

| Cu-ETP | O60 | All sizes | 25 min | 57 max | 58 min |

| H04 | For rod: Up to 10 incl. | 12 min | - | 56 min | |

| Over 10 to 25 incl. | 12 min | 89 min | 56 min | ||

| Over 25 to 50 incl. | 15 min | 83 min | 56 min | ||

| Over 50 to 75 incl. | 15 min | 71 min | 57 min | ||

| Over 75 | 15 min | - | - | ||

| For bar: Up to 10 incl. thickness and up to 110 incl. in width | 10 min | 89 min | 56 min | ||

| All other sizes | 15 min | 71 min | 57 min |

According to JIS H 3250

| Alloy | Temper | Rod & Bar Strength(mm) | Tensile Strength(MPa) | Elongation(%) | Conductivity(MS/m) |

| Cu-ETP | O | 6 or over up to and incl. 10 | 195 min | 30 min | 58 min |

| ½ H | 6 or over up to and incl. 25 | 245 min | 15 min | 57 min | |

| over 25 up to and incl. 50 | 225 min | 20 min | 57 min | ||

| over 50 up to and incl. 75 | 215 min | 25 min | 57 min | ||

| H | 6 or over up to and incl. 25 | 275 min | - | 56 min |

According to JIS H 3140

| Alloy | Temper | Rod & Bar Strength(mm) | Tensile Strength(MPa) | Elongation(%) | Conductivity(MS/m) |

| Cu-ETP | O | 2.0 or over up to and incl. 30 | 195 min | 35 min | 58 min |

| ½ H | 2.0 or over up to and incl. 30 | 215-275 | 25 min | 57 min | |

| ¼ H | 2.0 or over up to and incl. 20 | 245-315 | 15 min | 57 min | |

| H | 2.0 or over up to and incl. 10 | 275 min | - | 56 min |

It is mainly used for making electric equipment such as generator, bus, cable, switchgear, transformer and heat exchanger, pipe, flat plate collector of solar heating device.

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.