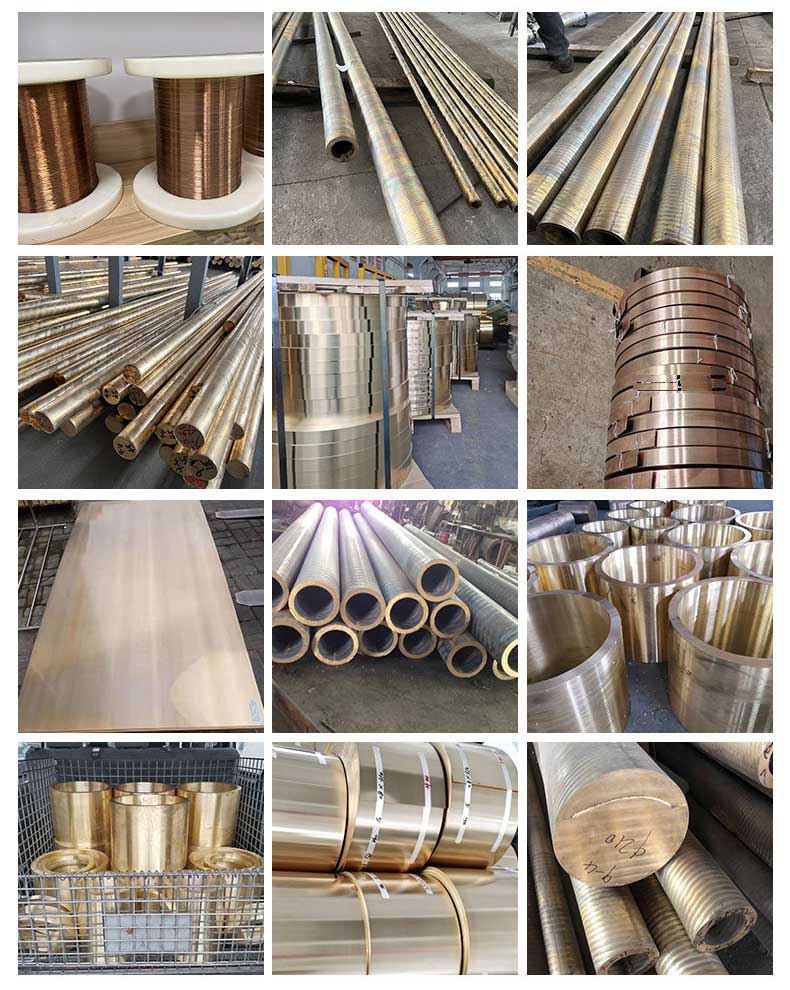

Tin Zinc Bronze

Excellent Mechanical Properties: Our tin bronze tubes have excellent mechanical properties, including high strength, wear resistance and toughness.

Corrosion Resistance: This alloy has excellent corrosion resistance and is suitable for use in marine and industrial environments.

Wide range of applications: It is versatile and can be used in various industries such as aerospace, defense and industrial machinery.

Customized composition: It offers the flexibility to customize the chemical composition to provide tailor-made solutions to meet specific application requirements.

Email: [email protected]

WhatsApp: 0086-13788924073

Our tin bronze alloys are known for their excellent properties and specifications. These alloys are favored for their high strength, low-speed performance and durability, making them ideal for a variety of applications. Their composition includes copper and tin, which provide excellent corrosion resistance and are therefore suitable for use in marine and industrial environments.

It is widely used in gears, bushings, bearings, pump impellers, piston rings and steam fittings. We can also customize formulas according to customer requirements and provide tailor-made solutions to meet the special needs of various industries.

Special sizes and shapes are available, such as U/L/T shapes.

The wall thickness of the pipe material ranges from 8mm to the outer diameter of 100mm.

Square materials are available with thickness greater than 8mm.

Round rods are available in diameters from 20mm to 212mm.

We can provide customized services according to customer needs.

| category | China | Russia | United States | U.K. | France | Germany | Japan | ISO | ||||||

| GB | YB | ΓOCT | ASTM | CDA | FS | SAE | BS | NF | AIR LA | DIN | JIS | |||

| Lead brass | HPb63-3 | HPb63-3 | ЛC63-3 ЛCЦ 63-3 |

C34500 C34700 |

345 347 | 345 347 | CA345 CA347 | CZ119 CZ124 | - | - | CuZn36Pb1.5 CuZn36Pb3 |

2.0331 | C3560 | CuZn35Pb2 CuZn36Pb3 |

| HPb63-0.5 | - | C34800 | - | - | - | - | - | - | CuZn37Pb0.5 | 2.0332 | - | - | ||

| HPb63-0.1 | HPb63-0.1 | - | C34900 | - | - | - | - | - | - | CuZn37Pb0.5 | 2.0332 | - | - | |

| HPb62-0.8 | HPb62-F | - | C35000 C37000 |

371 | - | CA371 | - | - | - | - | C3501 | CuZn36Pbl | ||

| HPb61-1 | HPb61-1 | ЛC60-1 | C36500 C36700 C37000 |

- | - | - | CZ123 | - | - | CuZn39Pb0.5 | 2.0372 | C3710 | CuZn40Pb | |

| HPb60-2 | HPb60-2 HPb60-3 |

ЛC60-2 | C36000 | - | - | - | CZ120 | - | - | - | - | C3713 C3604 |

CuZn38Pb2 | |

| HPb59-2 | HPb59-1A | ЛC59-1B | C35300 | - | - | - | - | - | - | - | C3771 | - | ||

| HPb59-1 | HPb59-1 HPb59-1B |

ЛC59-1 | C37800 | - | - | - | CZ122 | Cu-Zn40Pb | - | Cu-Zn39Pb2 | 2.0380 | C3710 | CuZn39Pb2 | |

| HPb58-3 | HPb59-3 | ЛC59-3 | C38000 | - | - | - | CZ121 | - | - | CuZn39Pb3 | 2.0401 | C3603 | CuZn39Pb3 | |

| Tin brass | HSn90-1 | HPb90-1 | ЛO90-1 | C41300 C41100 |

- | - | - | - | - | - | - | - | - | - |

| HSn70-1 | HPb70-1 HPb70-1A |

ЛO70-1 ЛOM70-1-0.05 |

C44300 | 443 | - | - | CZ111 | CuZn39Snl | - | CuZn28Sn1 | 2.0471 | C4430 | CuZn28Sn1 | |

| HSn62-1 | HPb62-1 | ЛO62-1 | C46200 C46420 |

462 | 462 | CA462 | CZ112 | - | - | - | - | C4622 C4621 |

CuZn38Sn | |

| HSn61-0.5 | HSn61-0.5 HSn61-0.5A |

- | C48200 | - | - | - | CZ115 | - | - | - | - | C6711 | - | |

| HSn60-1 | HSn60-1 | Л060-1 | C46500 C46400 |

465 464 | 464 | CA464 | CZ113 | CuZn38Sn1 | - | CuZn39Sn | 2.053 | C4640 C4641 |

- | |

| Aluminum brass | HA177-2 | HA177-2 HA177-2A |

ЛA77-2 ЛAMЦ77-2-0.05 |

C68700 | 687 | - | - | CZ110 | CuZn22A12 | - | CuZn22A1 | 2.046 | C6870 C6872 |

CuZn20A12 |

| HA166-6-3-2 | HA166-6-3-2 | C67000 | 670 | - | - | - | - | - | - | - | - | - | ||

| HA167-2.5 | HA167-2.5 | - | - | - | - | - | - | - | - | - | ||||

| HA160-1-1 | HA160-1-1 | ЛAЖ60-1-1 | C67800 | 678 | - | - | - | - | - | CuZn37Al | 2.0510 | C6782 | - | |

| HAI59-3-2 | HAI59-3-2 | ЛAH59-3-2 | - | - | - | - | - | - | - | CuZn35Ni | 2. 0540 | - | - | |

| Silicon brass | HSi80-3 | HSi80-3 | ЛK80-3 | C69400 | - | - | - | - | - | - | - | - | - | - |

| Manganese brass | HMn58-2 | HMn58-2 | ЛMЦ58-2 | C67400 | - | - | - | - | - | - | CuZn40Mn | 2.0572 | - | - |

| HMn57-3-1 | HMn57-3-1 | ЛMЦA57-3-1 | - | - | - | - | - | - | CuZn35Ni | 2.0540 | - | - | ||

| HMn55-3-1 | HMn55-3-1 | - | - | - | - | - | - | - | - | - | - | |||

| Iron brass | HFe59-1-1 | HFe59-1-1 | C67820 | - | - | - | - | - | - | CuZn39Sn | 2.0530 | C6782 | CuZn39AlFeMn | |

| HFe58-1-1 | HFe58-1-1 | ЛЖC58-1-1 | - | - | - | - | CZ114 | - | - | CuZn40Ni CuZn40Mn |

2.0571 2.0572 |

- | - | |

| Tin bronze | QSn4-3 | QSn4-3 | BPOЦ4-3 | - | - | - | - | - | - | - | - | - | - | CuSnZn4 |

| QSn4-4-2.5 | QSn4-4-2.5 | BPOЦC4-4-2.5 | - | - | - | - | - | - | - | - | - | - | - | |

| QSn4-4-4 | QSn4-4-4 | BPOЦC4-4-4 | C54400 | 544 | - | - | - | - | - | - | - | C5441 | - | |

| QSn6.5-0.1 | QSn6-5-0.1 | FPO Φ 6.5-0.15 | 519 | - | - | PB100 | - | - | - | - | - | - | ||

| QSn6.5-0.4 | QSn6.5-0.4 | bPO Φ 6.5-0.4 | C51900 | 519 | - | - | PB103 | CuSn6P | - | CuSn6 | 2.1020 | C5191 | CuSn6 | |

| QSn7-0.2 | QSn7-0.2 | 5PO Φ 7-0.2 bPO Φ 8-0.3 |

C52100 | 521 | - | CA521 | PB104 | - | - | CuSn8 | 2.1030 | C5212 | CuSn8 | |

| QSn4-0.3 | QSn4-0.3 | bPO Φ 4-0.25 FPO42-2.25 |

C51100 | 510 511 | - | CA510 | PB101 | - | - | CuSn4 | 2.1010 | C5101 | CuSn4 | |

| Aluminum bronze | QA15 | QAI5 | BPA5 | C60600 C60800 |

- | - | CAI01 | CuAl6 | - | - | CuAl5 | 2.0916 | - | CuAl5 |

| QAI7 | QA17 | 5PA7 | C61000 | - | - | - | CA102 | - | - | CuAl8 | 2.0920 | - | CuAl8 | |

| QAI9-2 | QA19-2 | BPAMЦ10-2 BPAMЦ9-2 |

- | - | - | - | UZ23A4 | CuA19Mn | 2.0960 | - | CuAl9Mn2 | |||

| QA19-4 | QA19-4 | FPAЖ9-4 | C61900 | - | - | - | CA03 CA106 | - | - | CuAl18Fe CuAll0Fe |

2.0930 2. 0936 |

- | CuAl18Fe3 CuAll0Fe3 |

|

| QAI10-3-1.5 | QA110-3-1.5 | 5PAXЖMЦ10-3-1.5 | - | - | - | - | - | - | - | CuAllOFe | 2.0936 | C6161 C6161 |

- | |

| QA110-44 | QAI10-4-4 | 5PAЖH10-4-4 | C63000 C63200 |

630 | - | - | CAI04 CAI05 |

CuAI9Ni5 -Fe3Mn |

BOK4 | CuAlloNi | 2.0966 | C601 | CuAl1l0 -Fe5Ni5 |

|

| QA111-6-6 | QA111-6-6 | - | - | - | - | - | CuAll1Ni | 2.0978 | C6280 | - | ||||

| Beryllium bronze | QBe2 | QBe2 | ɓBɓ62 | C17200 C17300 |

- | - | - | CuBe2 | UBe2 | CuB2 | 2.1247 | C1720 | CuBe2 | |

| QBel.9 | QBel.9 | ɓPɓHT1-9 | C17200 | 172 | - | CA172 | CuBe1.9 | |||||||

| QBel.7 | QBel.7 | ɓPɓHT1-7 | C17000 | 170 | - | CA170 | CB101 | CuBel.7 | CuBel.7 | 2.1245 | C1700 | CuBel.7 | ||

| Silicon bronze | QSi1-3 | QSi1-3 | ɓPɓKH1-3 | C64700 | - | - | - | DTD498 | - | - | CuNi2Si CuNi3Si |

2.0855 2.0857 |

- | CuNi2Si |

| QSi3-1 | QSi3-1 | ɓPɓKMЦ3-1 | C65500 C65800 |

- | - | - | CS101 | - | - | CuSi3Mn | 2.1525 | - | CuSi3Mnl | |

| Manganese bronze | QMnl.5 | QMn1.5 | - | - | - | - | - | - | - | - | CuMn2 | 2.1363 | - | - |

| QMn5 | QMn5 | ɓPɓЦ5 | - | - | - | - | - | - | - | CuMn5 | 2.1366 | - | - | |

| Cadmium Bronze | QCd1.0 | QCd1.0 | - | C16200 C16201 C16500 |

162 | - | C108 | - | - | - | CuCdl | 2.1266 | - | CuCd1 |

| Ordinary white copper | B10 | B10 | - | C70600 | - | - | - | CN102 | Cu-Nil0FelM | - | - | - | - | - |

| B19 | B19 | MH19 | C71000 | 710 | - | - | CN104 | CuNi20Mn1Fe | - | CuNi20Fe | 2.0878 | C7100 | CuNi20Mn1Fe | |

| Iron-nickel copper | BFe10-1-1 | MHЖMЦ10-1-1 | C70600 C70610 |

- | - | - | CN102 | - | CuNi10Fe | 2.0872 | C7060 | CuNi10Fel Mn | ||

| BFe30-1-1 | BFe30-1-1 | MHЖMЦ30-1-1 | C71630 C71640 |

715 | - | CA715 | CN107 CN106 |

CuNi30Mn1Fe | - | CuNi30Fe | 2.0882 | C7150 | CuNi30Mnl Fe | |

| Manganese cupronickel | BMn3-12 | BMn3-12 | MHMЦ13-12 | - | - | - | - | - | - | - | CuMn12Ni | - | - | - |

| BMm40-1-5 | BMn40-1.5 | MHMЦ40-1.5 | - | - | - | - | - | - | - | - | - | - | - | |

| BMn43-0.5 | BMn43-1.5 | MHMЦ43-1.5 | - | - | - | - | - | - | - | CuNi44 | 2.0842 | - | CuNi44Mnl | |

| Zinc cupronickel | BZn15-20 | BZn15-20 | MHЦ15-20 | C75400 | 754 | - | - | NS105 | CuNi15Zn22 | CuNi12Zn24 CuNi18Zn20 |

2.0730 2.0740 |

C7521 | CuNi5Zn21 | |

| Aluminum white copper | BAl13-1 | BAl13-3 | MHA13-3 | - | - | - | - | - | - | - | - | - | - | - |

We also provide CNC precision machining services for our clients, covering industries such as energy, petrochemicals, steel, engineering machinery, plastics, prevention and control, hydraulics, healthcare, and food. Please feel free to send us drawings for inquiries.